High Tensile Steel Rockfall Mesh

- Product Description

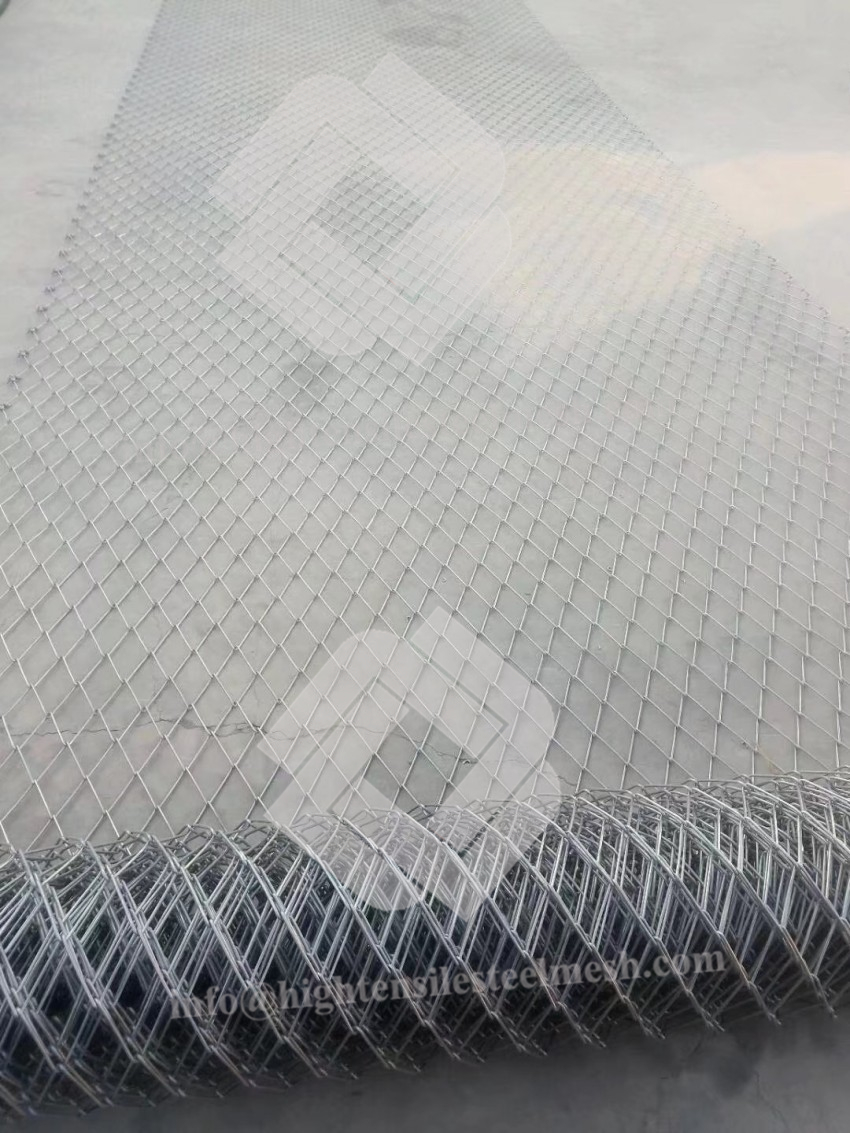

High Tensile Steel Rockfall Mesh is made of 2mm, 3mm or 4mm high-tensile steel wire with a tensile strength of no less than 1,770N/mm². The specifications of High Tensile Steel Rockfall Mesh are

including G65/3, G65/4, G80/4, G80/3, G80/2, G45/2 etc. Together with a pattern of bolting or anchoring, the mainly aplication area: Soil, strongly weathered slope reinforcement, river bank erosion

control, soil and water loss control, Slope greening, etc.

Main Components of High tensile steel rockfall mesh system: High tensile rockfall mesh, Steel bar anchor or Wire rope anchor, Spike Plates, Edge wire rope, Clip T3, Clip T2, Erosio Mat etc.

Components of High Tensile Steel Rockfall Mesh System

The High Tensile Steel Rockfall Mesh System consists of four main components that are carefully coordinated with each other:

1). High Tensile Steel Rockfall Mesh

High Tensile Steel Rockfall Mesh is made of high tensile steel wire 2mm, 3mm or 4mm with an ultimate tensile strength of 1770 N/mm2.2). High Tensile Steel Rockfall Mesh - Spike Plates

Rigid spike plates that are reinforced with ribbing ensure optimal load transmission from soil or rock anchors to the High Tensile Rockfall Mesh.These spike plates are placed over the anchor heads and tightened to pre-tension the mesh onto the slope.The spike plates are galvanized and have dimensions of 13.0''*7.5"*0.4"(330mm*190mm*10mm/8mm).

3). High Tensile Steel Rockfall Mesh - Connection Clips

The connection clips high tensile strength steel wire connection clips enable mesh sections to be joined without overlapping and still guarantee one hundred percent transfer of forces.These claw are hot dip galvanized and consist of0.25"(6mm) thick steel spiral.

4). Soil or Rock Nails

Adapted to the local soil and rock static requirements, the HIGH TENSILE ROCKFALL MESH can be anchored in accordance with our dimensioning concept with commercial soil or rock nails.The main anchors of the system are installedin a grid typically from 6.6 to 16.4 ft (2.0 to 5.0m) horizontal and vertical spacing.Actual spacing depends upon the results of site analysis and modeling.Anchor consist of commercially available steel bars ranging from 1.0 to 1.25 ft (25 to

32mm). Selfdrilling grout injection anchors are also permitted.Additional anchors may also be used to provide added support at boundaries and in low points and hollows.

- Related Products

- [Return Home] [Print] [Go Back]

Products Search

Contact Us

Contact Person:

SamTel:

+86-185-31864500Fax:

+86-311-80771861E-mail:

sales@hightensilewiremesh.com-